|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

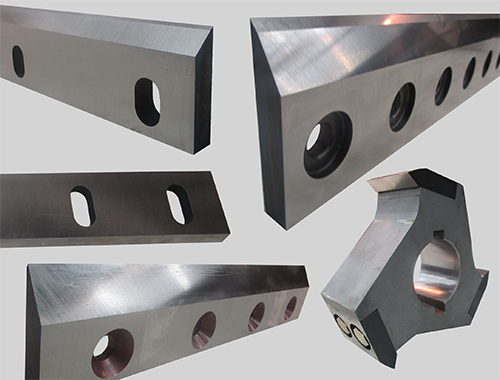

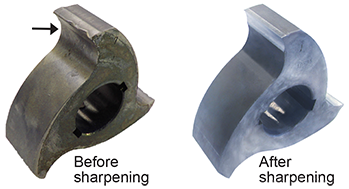

Services For Plastics can resharpen almost all makes and models of blades and knives at a significant cost savings over new blades. SFP resharpens all granulator knives including bed knives, rotating fly knives, Wortex/Conair fly knives and helical knives.

The condition of your grinder bed knives and rotating knives is key to grinder and granulator performance. Having blades that are properly sharpened will:

● Increase Cutting Rate Efficiency,

● Decrease Fines, and

● Decrease Noise.

EPIC Sharp® Granulator Blade Edges provides the highest quality steel and dimensional tolerances that you can find for your blades and knives.

For more information, click here.

Our skilled sales engineers are ready to advise and recommend solutions.

Email: Sales@ServicesForPlastics.com

Phone: 800-627-1033

The sharpening cost is calculated by the size of the blade, the number of edges, angle of edges.

$$$ Per inch for each angle

Keen Edge Rotary Blade

(Single-Angle)

$$$ Per inch for each angle

Reverse Bevel Rotary Blade

(Double-Angle)

$$$ Per inch for each angle

High Shear Rotary Blade

(Double-Angle)

Segmented Helical Fly Knives

(3-Tooth)

$$$ Per tooth

Services For Plastics, Inc. has been producing blades and knives since 1981. Our knowledge and expertise spans the entire mainstream brands offered in North America. Click links below to see models, images and dimensions for your blades and knives.

![]()

Home | Request a Quote | Place an Order | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2024 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy