|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

A thermocouple is a temperature measuring device consisting of two conductors of dissimilar metals or alloys that are connected only at the ends. When the ends are at different temperatures, a small voltage is produced in the wire that can be related directly to the temperature difference between the ends. If the temperature at one end is known, the temperature at the other end can be determined.

Thermocouple wire or extension grade wire is used to connect the thermocouple to the sensing or control instrumentation. The conditions of measurement determine the type of thermocouple wire and insulation to be used. Temperature range, environment, insulation requirements, response, and service life should be considered when selecting a wire type. There are two common types of thermocouple wire, Type J and Type K.

Type J (Iron/Constantan™)

Type J thermocouples are used in vacuum, oxidizing, inert or reducing atmospheres. Iron element oxidizes rapidly at temperatures exceeding 1000°F (538°C), and therefore heavier gauge wire is recommended for longer life at these temperatures.

Type K (Chromel™/Alumel™)

Type K thermocouples are used in oxidizing, inert or dry reducing atmospheres. Exposure to vacuum is limited to short time periods. Must be protected from sulfurous and marginally oxidizing atmospheres. Reliable and accurate at high temperatures.

Grounded TCs

The thermocouple junction is connected to the tip of the metal enclosure. Being connected to the sheath of the enclosure affords protection to the thermocouple and excellent response.

Ungrounded TCs

The thermocouple is isolated from the metal sheath and for this reason gives up a little response time. By being electronically insulated, this design is not subjected to picking up electrical noise. Most newer Van Dorns, and some other machines, require ungrounded thermocouples.

SS Flexible Armor

![]()

SS Overbraid

![]()

Adjusting Spring

![]()

Adjustable Depth Thermocouples can easily adjust to any immersion depth -- saving time and money. Simply insert the adjustable thermocouple probe into the thermocouple adapter well. Then the thermocouple's locking cap is rotated up or down to the proper immersion depth and locked onto the adapter. Spring compression acts to keep the probe firmly seated in the well. This assures for rapid heat transfer and accurate sensing. The "AO" series has the bayonet cap on an 8" spring and allows for 7" of adjustable immersion. The "AA" series has the bayonet cap on the flexible armor and allows for full 8" length adjustable immersion. Both series have leadwire rated to 900°F maximum temperature.

Click Here to View Part Number and Specifications for AA Series Adjustable Depth Thermocouples

Click Here to View Part Number and Specifications for AO Series Adjustable Depth Thermocouples

Bayonet Thermocouples are a fixed immersion thermocouple with compressible spring and locking cap. Bayonet TCs are well suited for applications requiring longer immersion depths. The probe of the bayonet TC is more rigid and provides a more positive contact in the deeper well. The compressible spring outer covering and its locking cap hold the probe securely in place. 90° bayonet TCs are often selected for use where space is at a premium and the 90° bend allows for a tighter, neater installation. All bayonet TCs have flexible extensions (overbraid or armor), ideal for connection to near or distant junction boxes.

Compression TCs have an adjustable attaching device that eliminates the need for an adapter. Compression TCs allow for the final adjustment of immersion depth to be made at the time of installation. They are ideal for the monitoring of liquids or gasses since they seal the process from the atmosphere.

Threaded Nozzle Thermocouples measure the temperature of the nozzle, when placed in a threaded shallow drill hole on the injection nozzle. There is no direct contact with the material flow. These TCs are a must for nozzles with minimal wall thickness between the inside bore and hex flat. Threaded Nozzle TCs come with a threaded rotatable sleeve bolt, which turns independently of the extension leads for easy installation or removal.

Click Here to View Part Number and Specifications for TN Series Threaded Nozzle Thermocouples

Spade Thermocouples measure the surface temperature by being slid underneath heater bands or held in place with a strap. They are very flat and can be placed in the gap where the two halves of a heater band come together. The heater's locking mechanism secures it in place. When used under heater bands in the nozzle area, it is relatively safe from damage by plastic back-up.

Click Here to View Part Number and Specifications for ST Series Spade Thermocouples

Ring Thermocouples also measure surface temperature, but are bolted to molds, platens and nozzles. They are often connected in parallel with another thermocouple to control at an average temperature. An example would be the connection of a ring thermocouple, measuring the surface temperature of the barrel, and a bayonet thermocouple, measuring deep inside the barrel's wall. The resulting reading would enable closer control for a more uniform temperature of the plastic melt. Note that the connected thermocouples must be of the same type and resistance.

Click Here to View Part Number and Specifications for RT Series Ring Thermocouples

Melt Bolt Thermocouples are immersed directly into the melt for a more accurate reading. They mount in the extruder barrel neat the head. The closed end sensitive portion of the tip is immersed directly into the plastic. There are two styles available. The Fiberglass type has a fiberglass insulated thermocouple element in a stainless steel probe. The MgO type obtains its insulation from magnesium oxide which is tightly compressed between the thermocouple wires and the stainless steel sheath.

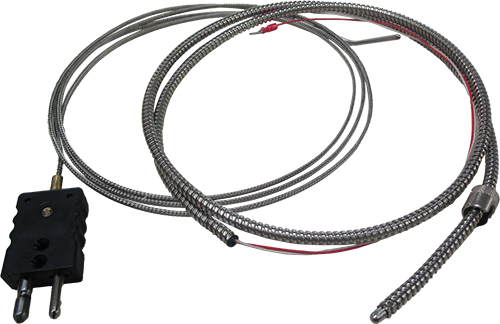

Flexible Thermocouple Extensions act as an "extension cord" to provide connections between sensors, jack panels, or instruments. Extensions are constructed with thermocouple wire or thermocouple extension wire.

Pipe Clamp Thermocouples are attached to an all stainless steel worm gear hose clamp and are convenient where drilling or tapping is impractical.

A Resistance Temperature Detector (RTD) is a temperature sensing probe of finely wound platinum wire that displays a linear resistance increase for a corresponding temperature increase. RTDs are built on the principle that most metals have a positive charge in electrical resistance with a change in temperature. When quality control is of extreme importance, an RTD is unequalled for accuracy and repeatability. RTDs do not require cold junction compensation or special extension wire. RTDs are available in two different temperature ranges and leadwire types, the L Series and the M Series. All sheaths and tips are manufactured from 316 stainless steel for superior resistance to corrosion, abrasion, and deterioration.

2-Wire Configuration

A 2-wire configuration is a less accurate style of RTD assembly. The added lead wire resistance is not compensated for by the temperature controller or transmitter used to monitor the resistance of the RTD. This increased resistance will cause the display temperature to be higher than the actual temperature.

3-Wire Configuration

A 3-wire configuration is the most common configuration because it is both cost effective and accurate. The added lead wire resistance is calculated by the controller through the third wire of the RTD assembly. The leadwire resistance is then subtracted from the loop resistance and true resistance is found. Through this method, the controller or transmitter "compensates" the lead wire giving an accurate temperature display.

When quality control is of extreme importance, an RTD is unequalled for accuracy and repeatability. RTDs do not require cold junction compensation or special extension wire. Like the Adjustable Depth Thermocouples, Adjustable Depth RTDs easily adjust to any immersion depth. When rotated, a threaded locking cap moves up and down the tension spring to adjust the depth.

Fixed Bayonet RTDs are a fixed immersion RTD with compressible spring and locking cap. Bayonet RTDs are well suited for applications requiring longer immersion depths. The probe of the RTD is more rigid and provides a more positive contact in the deeper well. The compressible spring outer covering and its locking cap hold the probe securely in place. 90° bayonet RTDs are often selected for use where space is at a premium and the 90° bend allows for a tighter, neater installation. All bayonet RTDs have flexible extensions, ideal for connection to near or distant junction boxes.

Compression RTDs have an adjustable attaching device that eliminates the need for an adapter. Compression RTDs allow for the final adjustment of immersion depth to be made at the time of installation. They are ideal for the monitoring of liquids or gases since they seal the process from the atmosphere.

Click here for technical information about thermocouples & RTD's

![]()

Home | Request a Quote | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy