|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

Our thermal insulation products for plastics process has a return on investment of less than 12 months and often times much quicker depending on: process type, temperature, and cost per KWH. Typical time to recoup insulation cost is based on operating machines 24 hours per day, 5 days per week paying $0.15 per KWH. Process heat loss costs the industry hundreds of millions of dollars annually. No other energy project will pay for itself as quickly and with as little upfront effort.

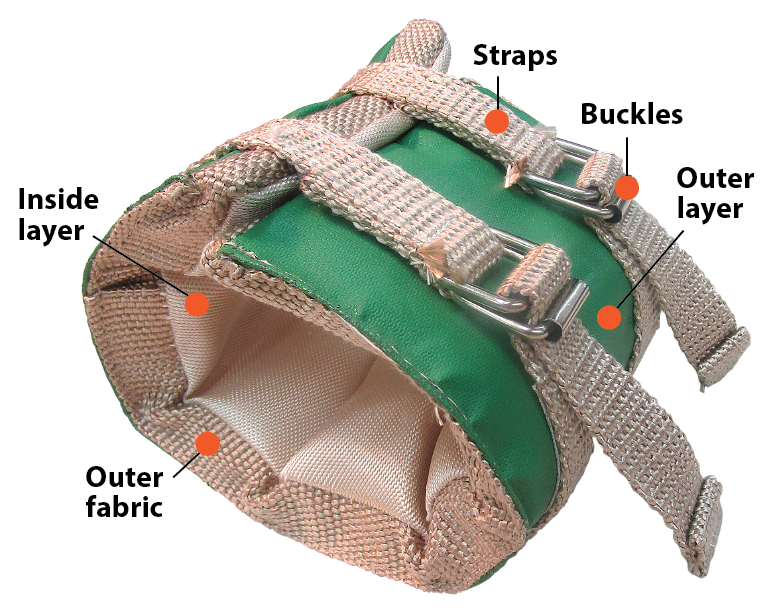

Outer layer: Made of PTFE coated fiberglass cloth can withstand temperatures up to 550°F.

Outer fabric: Made of silica cloth can withstand temperatures up to 1800°F.

Inside layer: High-density ceramic fiber can withstand temperatures up to 2000°F.

Straps: Made with fiberglass yarn can withstand temperatures up to 1000°F.

Buckles: Made of nickel steel.

Circle the barrel with heater bands and thermocouples; their wires run along the inside of the blanket.

Cover the machine's heated processing elements.

Customizations are available.

Please contact us at 800-627-1033 or by email at

Sales@ServicesForPlastics.com

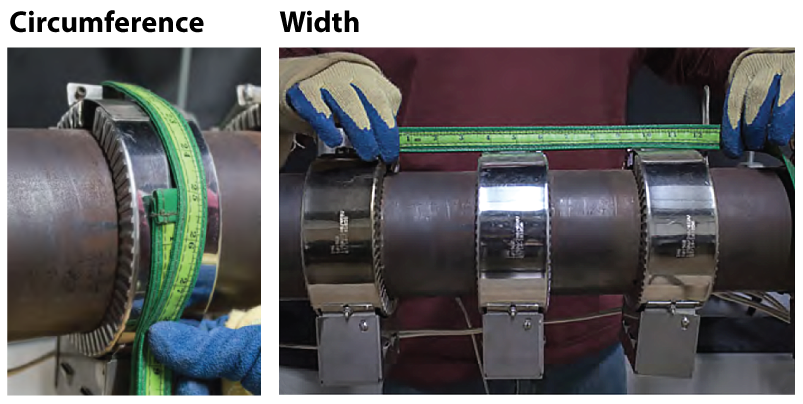

WARNING: When installing or measuring for an insulated product, please follow all safety precautions and use proper and adequate protective safety aids, such as protective gloves and suitable clothing. Keep all metal objects away from heater bands. Never use metal tape for measuring purposes. Failure to do so may result in injury.

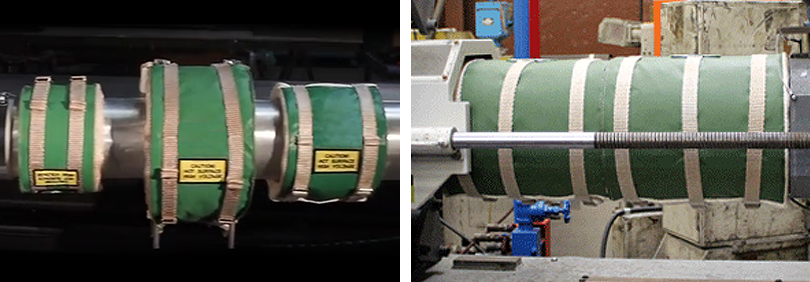

Installing jackets is quick and easy. Simply place jacket over the object, fasten straps, but Do Not Overtighten.

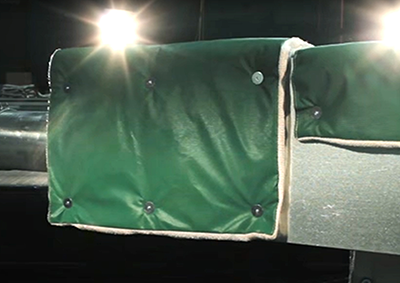

Throw blankets are attached by optional straps or magnets.

Unlike most removable thermal insulation systems ours are standard, readily available off-the-shelf components to meet any custom fabricated requirement. Virtually any component in our product line can be modified to fit your needs be it simple or highly complex, Services For Plastics can help. Contact us at 800-627-1033 or email us at Sales@ServicesForPlastics.com

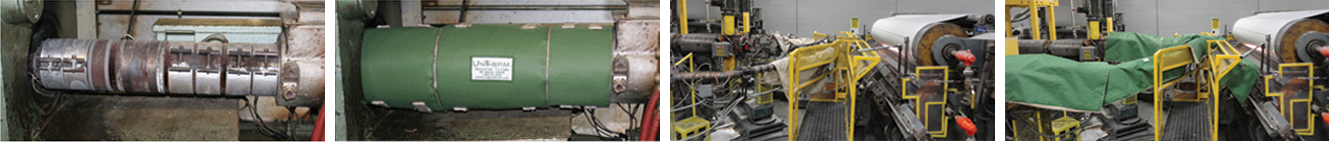

These are removable and reusable jackets that wrap around a barrel, or other equipment, holding in process heat. They are easy to maneuver and simple to install used in a variety of applications. They reduce energy costs by maintaining constant process temperatures.

These are unique, removable and reusable insulation blankets, protecting at temperatures up to 1500°F. Throw Blankets are lightweight, modular, and easy to maneuver. The possibilities for draping or magnetizing the throw blankets to an object are virtually limitless.

Straps are precisely spun using fiberglass yarn. The strength of the nickel steel roller buckles and design flexibility allow for an easy adjustment and exact fit.

Throw blankets are manufactured with or without magnets to suit your needs. Magnets can be purchased separately.

WARNING: Magnets are not to be used around electrical connections.

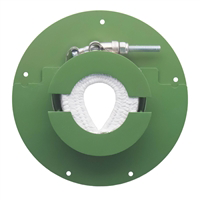

This device protects heater bands, wiring and insulation from the expensive and damaging effects of drool blowback. Plastic drool collects on the shield instead of damaging or destroying your equipment. It can withstand high temperatures up to 700°F.

For an overview on the DroolShieldŽ device, CLICK HERE.

![]()

Home | Request a Quote | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy