|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

NOTE: If sending in a screw for inspection that has plastic resin on it, then a SDS for the resin MUST accompany the screw.

American Leistritz, Baker & Perkins (APV), Berstorff, Bucher, Century Extrusion, Cincinnati Milacron, Coperion, Cosomoplast, Davis Standard, Egan, Farrel, Ikegar, JSW (Japan Steel Works), Krauss Maffei, Maris, Reifenhauser, Theysohn, Toshiba, W&P (Werner & Pfleiderer), Welding Engineers

In most cases, twin screws can be rebuilt at a considerable cost savings over replacement. Individual elements can be replaced as necessary. In addition, we can change element order, add or eliminate mixing and kneading sections and provide general optimization of twin screw profile. Services for Plastics, Inc. can also check twin screws for shaft straightness and shaft twist.

Replacement elements can be manufactured from D-2 Heat Treated Steel, CPM-9V Heat Treated Steel or CPM-10V Heat Treated Steel for maximum abrasion resistance.

When having problems with increased scrap and decreased throughput, SFP is your answer. Our engineers have over 50 years of combined twin screw experience. We have the capabilities to understand your unique application and to assist in the design that will yield the highest throughput with the best melt quality. For high shear, low shear, large throughput and high RPM speed, we have your answers.

To print Incoming Freight Policy. Download File

A. Use a strong, reusable wooden crate to transport barrel or feedscrew. Build one if not available.

B. Put the part in the crate and secure wooden blocks to prevent it from rolling.

C. Secure it further with several wooden 2 x 4s, cut to the crate's width. Position 2 x 4s directly above part and secure with nails.

D. Close the crate and secure lid with screws and banding.

E. Crate should be built for moving with a forklift.

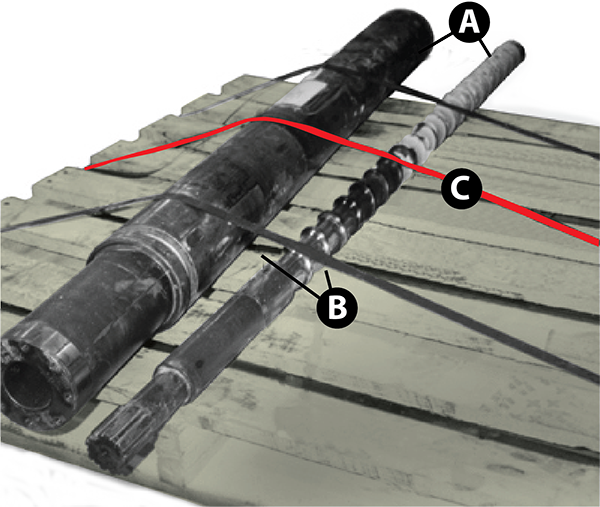

A. Parts hanging unsupported over edge of skid; potential damage.

B. No supports to prevent parts from rolling into each other; potential damage.

C. Banding not strong enough to hold parts immobile; potential loss of parts.

We appreciate your adherence to our suggestions on transporting your parts to our facility. We aim to provide the best service possible. - Services For Plastics, Inc.

![]()

Home | Request a Quote | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy