|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

|

Tips for shipping barrels and feedscrews to SFP facility.

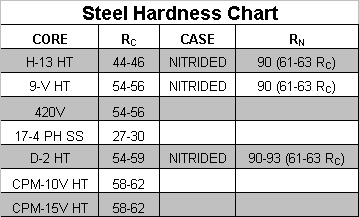

In most cases, barrels can be resleeved at a considerable cost savings over replacement. Most standard resleeving can be estimated over the telephone; however, phone estimates are not firm until an inspection has been completed. Standard resleeving consists of measuring the barrel, determining length of sleeve necessary to return to OEM specifications, machining out the old liner, resleeving with the desired material, tapping all threads, and polishing. You will be contacted with a firm price, and no work will be performed without your approval. There is NO CHARGE for inspection. Depending on your application, your barrel can be resleeved with one of the following liners:

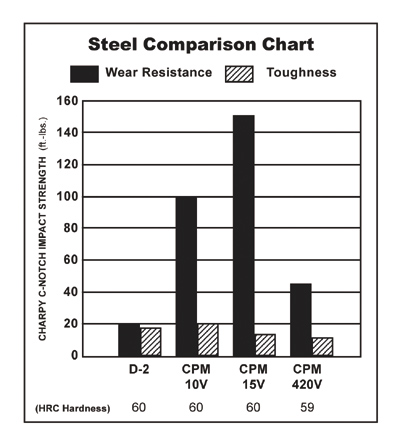

Our most popular D2 Tool Steel sleeve has been very successful in most molding applications including moderate concentrations of glass or mineral filled materials. One of the most wear resistant of the conventional tool steels, it is alloyed with 12% chromium and 1% vanadium which form very hard carbides. This high percentage of chromium gives it mild corrosion resisting properties in the hardened condition. D2 Tool Steel is thru-hardened to maximize its wear life.

Crucible's CPM® 10V Tool Steel has proven itself for most difficult molding applications such as continuous use of glass, mineral, ceramic, calcium, & metal filled plastic materials. This extremely wear resistant tool steel is manufactured by the particle metallurgy process which makes it possible to alloy a high percentage (9.75%) of vanadium, which forms the hardest of the tool steel carbides.

Crucible's CPM® 15V Tool Steel is the newest in the family of high vanadium, highly abrasion resistant CPM® tool steels. It contains 50% more hard vanadium carbides (14.5%) in its microstructure than CPM® 10V, to provide even higher wear resistance. CPM® 15V is intended for applications requiring exceptional wear resistance and where CPM® 10V is successful, but even longer life is desired.

Crucible's CPM® 420V is a stainless steel tool steel best suited for corrosion resistant applications. CPM® 420V is a higher performance upgrade for CPM® 440V. Corrosion resistance is significantly better than CPM® 440V, and wear resistance is about 25-50% better, due to the higher vanadium carbide content of the CPM® 420V (9% vanadium vs. 5.5-6% in CPM® 440V).

Crucible's CPM® S90V is a martensitic stainless steel to which vanadium and carbon have been added for exceptionally good wear resistance. CPM S90V offers substantial improvements in wear resistance over 440C and D2, and other high chromium steels, with corrosion resistance equal to or better than 440C. CPM S90V’s high vanadium content favors the formation of hard vanadium carbides instead of chromium carbides for wear resistance, leaving more free chromium available to provide corrosion resistance.

Other Services:

- We also repair bolt holes, threads, keyways, feed holes and ports.

- We specialize in super wear-resistant tool steel barrels, downsize/upsize conversions, and thermoplastic/thermoset conversions.

- We remove screws locked in barrels for a nominal fee.

(A SDS on the material being used when the machine seized MUST be supplied!)

Incoming Freight Policy

To print Incoming Freight Policy. Download File

- To help prevent loss during shipping, please attach a copy of your packing slip to the part itself, as well as the outside of the crate.

- Services for Plastics, Inc. will hold parts sent in for inspection for a maximum period of six (6) months, after which the parts will be scrapped at our warehouse (unless prior arrangements have been made).

- If sending in parts for inspection that has plastic resin on it or in it, then a SDS for the resin MUST accompany the parts.

- Parts to be returned to you will be shipped freight collect.

- All incoming parts for rebuilding, repairs, etc. must be shipped to SFP "Freight Prepaid" in a strong, reusable container (see examples below). The Bill-of-Lading should be marked: MACHINERY PARTS, STEEL, CLASS 85, FREIGHT PREPAID. Smaller items weighing 70 pounds or less should be shipped via UPS Prepaid. In the event that items are received "Freight Collect", our Receiving Department must obtain approval prior to accepting the shipment. If the shipment is accepted, you will be billed for the freight plus a $35.00 Processing Fee. SFP reserves the right to refuse the shipment. Terms for Freight Charges: Net 10 Days. A copy of the original freight bill will be sent with the invoice.

- If parts are received in a non-reusable container, SFP will build a crate to return the repaired parts, and the customer will be billed for the cost of the crate.

Preferred Packaging Method For Shipping Parts:

A. Use a strong, reusable wooden crate to transport barrel or feedscrew. Build one if not available.

B. Put the part in the crate and secure wooden blocks to prevent it from rolling.

C. Secure it further with several wooden 2 x 4s, cut to the crate's width. Position 2 x 4s directly above part and secure with nails.

D. Close the crate and secure lid with screws and banding.

E. Crate should be built for moving with a forklift.

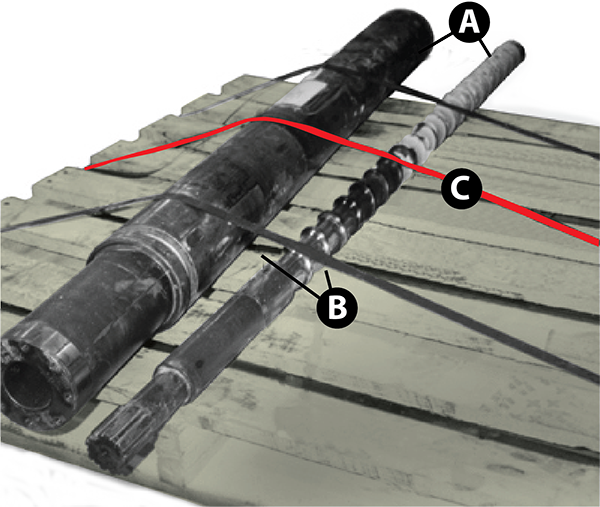

DO NOT Ship Parts As Shown In This Example:

A. Parts hanging unsupported over edge of skid; potential damage.

B. No supports to prevent parts from rolling into each other; potential damage.

C. Banding not strong enough to hold parts immobile; potential loss of parts.

We appreciate your adherence to our suggestions on transporting your parts to our facility. We aim to provide the best service possible. - Services For Plastics, Inc.

Manufacturers of High-Quality Products for the Plastics Molding Industry

Home | Request a Quote | Product Index | Online Catalog | Barrels & Screws | Electrical Products | Hoses & Fittings | Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

SERVICES FOR PLASTICS, INC.

800-627-10337925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy