|

Call Today 800-627-1033 |

|

|

|

|

||

|

|

||

Machine mounts are a fast, easy, and precise way to level your machinery and equipment. While significantly reducing noise, machine mounts also provide up to an 80% reduction in transmitted vibrations. This contributes to improved operation and quality, as well as isolating precision instruments.

Designed for use on machinery that does not require being fastened to the floor to prevent tipping, machine mounts are ideal for use on:

Machine mounts easily attach to machinery and equipment during initial installation, or when moving machinery from one place to another.No drilling, cementing or bolting machines to the floor.Simply attach the mount, adjust the leveling bolt, and tighten.

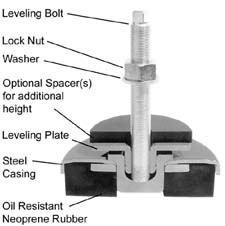

Precise LevelingThe precision fit between the leveling plate and rugged base leaves no room for horizontal sway.Horizontal forces and vibration are transmitted directly to the shock absorbing rubber sole.The heavy-duty mounting plate and finely threaded leveling bolt allow for accurate leveling.

Comply with OSHA RegulationsBecause the neoprene rubber sole provides an excellent friction barrier against creeping or walking, SFP machine mounts meet all OSHA anchoring requirements.

Vibration and Noise ControlImproved machinery operation, product quality, and isolation for precision equipment are just a few of the advantages to using machine mounts.The dampening effect of our machine mounts provides up to 80% reduction in transmitted vibrations.Vibration reduction also means an improved working atmosphere in surrounding areas.Reduction of noise at critical dB levels can, in some instances, permit compliance with OSHA noise level standards in a cost-effective manner.

Rapid and Economical Machinery Location

Because equipment mounted on machine mounts is not bolted to the floor and easy to pick up and move, significant savings of both time and money can be achieved when machinery relocation is necessary.

For Plastic Injection Molding Machines:

For Plastic Injection Molding Machines:

| STANDARD-DUTY MOUNTS | HEAVY-DUTY MOUNTS | ||||

| MM1M | MM2M | MM3M | MM3M-HD | MM4M | |

| Min. to Max Load per Mount | 400-1100 lbs. | 825-2200 lbs. | 1650-4400 lbs. | 3300-8800 lbs. | 6600-12,000 lbs. |

| Presses Strokes/min. - 125 max. Strokes/min. - 160 max. Strokes/min. - 200 max. |

400-500 200-400 200-300 |

800-1200 600-1000 400-600 |

1400-2400 750-1500 500-1000 |

3000-4000 2000-3000 1000-2000 |

6000-8000 4000-6000 3000-4000 |

| Injection Machine Tonages | 500 Tons | 1000 Tons | 3000 Tons | 6000 Tons | 12,000 Tons |

| Diameter | 3.15" | 1.80" | 6.25" | 6.25" | 7.875" |

| Height to Top of Leveling Plate | 1.50" | 1.80" | 2.10" | 2.13" | 2.20" |

| Leveling Adjustment | .50 | .55 | .60 | .60 | .60 |

| Standard Leveling Bolt | M12 x 1.25 x 120 | M16 x 1.5 x 120 | M20 x 1.5 x 170 | M20 x 1.5 x 170 | M20 x 1.5 x 170 |

| Max. Machine Base Thickness | 1.50" | 1.80" | 2.10" | 2.13" | 2.20" |

|

|

||||||||||||||||||||||||||||

![]()

Home | Request a Quote | Product Index | Online Catalog |

Barrels & Screws | Electrical Products | Hoses & Fittings |

Molding Accessories | SDS Sheets | Credit Application | Terms & Conditions | About Us | Contact Us

7925 N. Clinton St., Fort Wayne, IN 46825-3113, USA

E-mail: Sales@ServicesForPlastics.com

Contact Webmaster regarding content or link problems

Copyright 1997-2026 | Services For Plastics, Inc. | All rights reserved. | Privacy Policy